PF-1200 Screw-Type Powder Color Feeder

Introduction

Comet’s PF-1200 screw-type color feeder is designed for precise metering of non-free-flowing powders and color pigments directly into the production machine feed throat. The PF-1200 uses a special screw designed with an open spiral and fixed internal core, which results in a highly accurate feed.

The PF-1200 is equipped with a cylindrical shaped stainless steel material hopper, which houses an agitator. The material hopper, agitator and metering screw are integrated into one complete package. Cleaning and making color changes is very easy, with the added bonus of being able to fill the material hopper outside of the production area. The agitator of the metering unit is changeable to enable metering of color concentrate and other coarse grained materials.

Two versions available:

The SMD version for injection machines has a step motor having an incremental accuracy of 1/100 of a revolution. The electrical control includes a digital readout and setting for the metering screw.

The DCD version has a DC drive motor for extrusion machines. It can be connected to the tachometer of the extruder (0-10V) to obtain synchronous operation between the machine and the feeder.

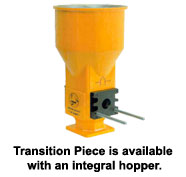

The modularly constructed transition piece enables several types of metering units to be mounted at once. For example, two SMD-1100s can be mounted for color concentrate and regrind coupled with a PF-1200 for a powder additive.

Features

- Material hopper, agitator, and metering screw are integrated into one complete package.

- Easily dismantle the unit for effortless cleaning and for filling the material hopper away from the production area.

- Modularly constructed transition piece enables several types of feeders (e.g. AC/IC-1100 or SMD) to be mounted at once.

- Unique screw designed with an open spiral and fixed internal core results in a highly accurate feed.