3DX-M Micro Compressed Air Resin Dryer

Introduction

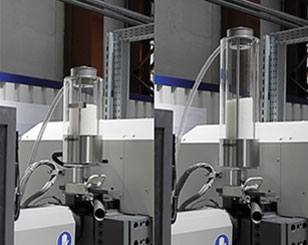

The 33DX-M Micro Compressed Air Resin Dryer is ideally suited for small and micro injection molding machines using dry hygroscopic plastic resins. It features a double wall of Borosilicate glass for optimal thermal protection, stepless adjustable material sensors in combination with an automatic hopper loading device, and a full range process controller just

like its “bigger brother,” the 3DX system.

There are three hopper sizes available: 2, 4 and 7 liters, and are available in two versions, 3DX-M Integral and 3DX-M Split. With the Integral version, the main components are built into one unit. With the Split version, the process air module and the hopper are separated allowing for a more flexible installation, improved ease of use, and to take the weight off the

molding machine’s feed throat. The throughput is from .05 to 4 kg/hr.

Features

- Process air with dewpoints of -13°F ( -25°C). (if required -85°F / -65°C).

- Air supply unit with process air pre-setup and micro controller.

- Detachable operating panel with an easy-to-read, large scale display.

- Extremely easy and intuitive using a guided 3-level menu logic.

- Automatic temperature controller with flexible electronic control.

- Totally adjustable material sensor combined with an automatic compressed air loading device.

- Automatic filling with adjustable filling level sensor.

- Automatic temperature controller with flexible electronic control.

- Direct feed throat mount.

- Easy installation, low maintenance and has the lowest energy consumption of dryers on the market today.

Options

- Claw Flange installed at the bottom of the dryer hopper (includes a fastener lever and fastener plat.

- Holding Frame with Wheels to engage a brake.

- Integrated Conveying Unit, the level sensor, installed on the drying hopper cover, can be plugged into a designated connection on the side of the hopper body.