CDD Honeycomb Matrix Dryer/Hopper Combo

Introduction

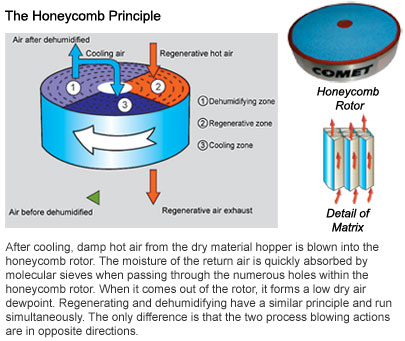

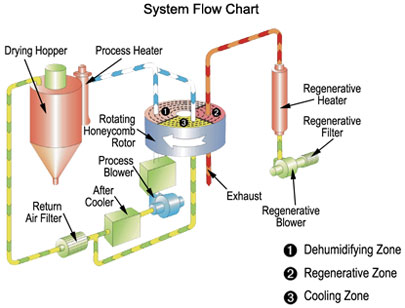

The energy efficient CDD series honeycomb matrix drying system combines dehumidifying and drying into a single unit, offering the latest in matrix rotor drying technology. A rotor slowly turns while a cycle of dehumidification, regeneration and cooling is repeated simultaneously providing a lower dewpoint than desiccant, compressed air, or vacuum dryers.

Because this closed-loop design operates in a continuous drying mode, it eliminates the risk of moisture re-absorption, keeping atmospheric moisture away from the freshly regenerated desiccant bed to eliminate dewpoint spikes during bed changeover.

The CDD is suitable for any hygroscopic resin such as PA, PC, PBT, PET and nylon drying applications involving large quantities of hygroscopic material.

Features

- Each model combines dehumidifying and drying functions into a single unit.

- The honeycomb rotor provides continuous closed-loop drying and requires less maintenance while eliminating contamination problems associated with desiccant beds.

- Under ideal conditions, maintains a dehumidified dry air dewpoint of at least -40°F (-40°C) or lower.

- Insulated drying hopper features down-blowing dry air and cyclone exhaust improving drying efficiency and reducing energy consumption.

- The dehumidifying section of the CDD features two coolers ensuring low return air temperatures and a low dewpoint.

- Space-saving, compact size for ease of movement.

- Microprocessor control system.

Options

- Dewpoint monitor to set the temperature values between -40° to +50°F (-40° to +10°C) depending on the plastic material, saving 0~10% total power consumption.

- Suction box and hopper loader for convenient material conveying.

- PLC control plus LCD touch screen for convenient centralized control.

- Regenerative plate heat exchanger to save 3-6% total power consumption.

- Drying plate heat exchanger to save 0~19% power consumption.

- Controllable drying capacity function. Once the name of the dried plastics material and per hour volume used is set, the system adjusts the air volume and consumption automatically. The volume used per hour can be set 40-100% of drying capacity saving total power consumption of 0~35%.