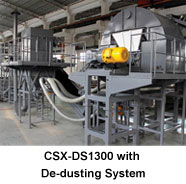

CSX-DS Extreme Duty, Dual Shaft Shredder

Introduction

Comet’s CSX-DS series dual shaft shredders are designed to shred large quantities of scrap metal and a range of waste materials including mixed materials with metal contamination. They are built for extreme-duty, delivering high torque gears and throughput. This shear-type, multi-purpose industrial shredder has a unique modular split chamber design providing excellent access to key components to reduce maintenance downtime and service costs.

Features

- Slow speed high torque shredding principle.

- Low noise levels without creating dust or flying particles.

- Rugged low maintenance design.

- Shock absorbing shaft couplings between gear boxes and blade shafts reduce operational stress.

- Extremely powerful blades and spacers manfactured from high quality, heat-treated steel are suitable for shredding or pre-shredding tough materials.

- Individual cleaning fingers mounted to the chamber sidewalls ensure quick discharge of shredded materials.

- Modular chamber design with split end-plates and bearing housings enables quick access to all key components.

- Advanced, adjustable sealing system prevents dust from damaging gears and bearings.

- Stand alone electrical control panel with Siemens PLC control system.

- Certified to the applicable CE safety standards.

Typical Applications

- Tires: car, truck, and off the road (earth movers)

- Electronic Waste & Scrap: components, consumables and subassemblies

- Bulky Waste: mixed household, municipal, industrial, and paper industry pulper waste

- Wood & Timber: pallets, C&D debris, etc.

- Aluminum: castings, profiles, etc.

- Steel: car body shells, sheet scrap, etc.