Bag Support Framework

Introduction

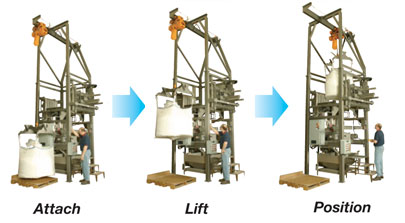

Comet’s Bag Support Framework is designed to safely support and contain a bulk bag so the operator never stands directly under the bag while lifting, positioning or bag discharging. The standard capacity of the framework is 4,000 lbs. and is constructed of 4″ sq. structural tubing. The upper frame section has 36″ of height adjustability to accommodate a wide range of bag sizes.

Features

- A-frame design with a capacity of 4,000 lbs. is engineered to exceed ANSI and ASME specifications for under-hung cranes and monorail systems.

- Easy placement of the bag hanger into the support framework by operator.

- Unique upper frame design utilizes a continuously welded 8″ I-beam to support the dedicated hoist and trolley.

- The lower frame’s 4″ x 4″, 3/16″ thick tubular uprights and cross braces enhance the structural integrity of the frame preventing the uprights from splaying as the bag is raised into position.

- The lower frame can be mounted on load cells for loss-in-weight operation.

- Frame mounted hoist controls increase operator safety by preventing the operator from positioning themselves directly under a full bag, as well as eliminating entanglement problems found with pendant style hoist controls.

- All utilities are pre-plumbed and pre-wired to a single connection point to reduce installation costs.

- A single 480V power supply, run to the main control panel, is all that is required to run the hoist, trolley and any other features included in a complete bulk bag discharging system.

- Various hoist and trolley options are available for ease of positioning the bag into the frame.

- A complete lower frame is available for applications where customers have an existing hoist and monorail system.