Tilt Tables

Introduction

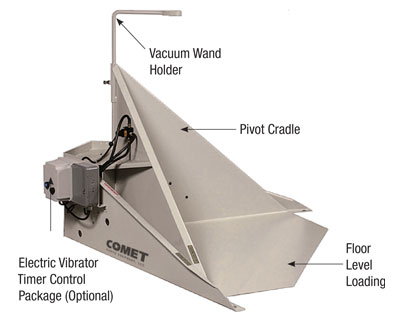

Comet’s floor level Tilt Tables reduce manual labor and operating costs associated with vacuuming material from gaylords, drums and other containers. The automatic tilting action directs the material towards the vacuum wand resulting in uninterrupted flow of material, thus eliminating the need for operators to continually reposition the wand in the container.

Containers, weighing up to 2,500 lbs., are set into the container tilt carriage at the floor-level loading position. As the vacuum take-away removes material from the container, the container weight will reach a preset activation weight. At the activation weight the container tilt action initiates and directs the material flow to the vacuum system wand. Comet’s tilt tables are designed to the unique requirements of each application; whether vibratory kits for non-free flowing material, container covers for dust control and contaminant protection, or custom cradle configurations for varied container types.

Features

- Automatic or manual tilt action to a maximum with minimal operator interaction.

- Pneumatic activation includes a complete pneumatic control system including a 3-position air valve and all necessary filter regulators.

- Patented safety stop keeps your operators free from harm by eliminating the potential for the cradle to unexpectedly lower due to a pneumatic system failure.

- Flow control adjusts operating speed to tip at heavier or lighter set points and comes factory preset at 43 PSI.

- Constructed of formed 7-gauge carbon steel or stainless steel.

- Adjustable height vacuum wand holder with a 3-1/2″ ID, providing 12″ of adjustment to accommodate various container heights.

- Pillow cradle is designed to accommodate containers up to 48″ square by approx. 60″ tall, but can be modified to accept other container sizes.

- A single air supply connection provides easy field installation.

Specifications

- Capacity: Rated at 2,500 lbs. in load position. 43 PSI precision regulator allows lifting to begin at approx. 900 lbs. to avoid material spillage.

- Framework: 7-gauge carbon steel.

- Size: Approx. 71″ wide x 52″ deep in the load position and 72″ wide x 80″ deep when in the maximum tilt position.

- Adjustable Vacuum Wand Holder: 31⁄2″ ID featuring 12″ of adjustment to accommodate various container heights.

- Load Design: Loaded at floor level into the 46.5″w x 46.5″d bucket of the tilter. The pivot bucket is designed to accommodate containers up to 48″ sq. x approx. 60″ tall (can be modified to handle other container sizes).

- Finish: Painted Metallic Gray.