PET Closed-Loop Crystallizer

Introduction

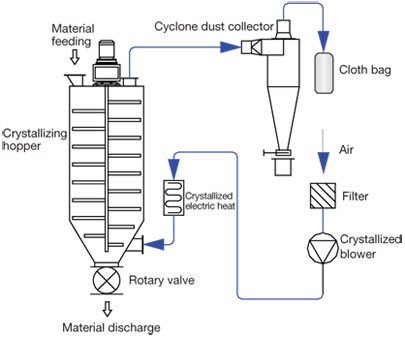

The CCR series closed-loop crystallizers are used to re-crystallize PET amorphous material before drying to prevent clumps from occurring. Once re-crystallized, the PET material can be conveyed to a material storage bin or directly into a drying hopper.

The system consists mainly of heating elements, an insulated hopper, and an agitator screw mixing device. After uncrystallized PET material is fed into the hopper, the system begins re-crystallization. The agitator screw slowly blends the material to prevent clumping.

Features

- Constant, fixed speed of agitator keeps PET material moving to prevent clumping as it is heated during the crystallization process.

- Simplifies and improves drying efficiency (even under high temperatures).

- Cyclone dust collector for dusty resin. Filter bag changing is reduced, extending the lifespan of the bag.

- Double overheat protector reduces the possibility of either mechanical or man-made heating problems.

- Tightly sealed rotary valve enables accurate, crystallized material output.

- Material level switch accurately detects the material level making operation more reliable.

- Negative pressure tester immediately tests filter ventilation and also cleans the filter to avoid blockage. An alarm sounds when the negative pressure is higher than the set value.

Options

- Accumulator with dehumidifier for direct dehumidification.

- Safety ladder for CCR-900U and above models.

- Auto loader, hopper receiver, magnetic base, and suction box for material conveying.

- Feed screw for stable, even conveying of uncrystallized material.

- External stainless steel pipeline.

Working Principle

The CCR monitors both the level and temperature of the resin in the top of the hopper and automatically regulates the speed the material moves through the hopper so every pellet is crystallized before discharge.

Once material filling begins, the CCR automatically begins agitating and heating the material. The agitator screw slowly blends the material to prevent clumping and material degradation during the heating process. A temperature sensing probe detects when the crystallized temperature value has been reached.

As the material level in the hopper gradually decreases, a filling device begins supplying uncrystallized PET material. When the temperature sensing probe detects that the correct temperature value has been reached, it stops conveying material. If the temperature rises again to reach the set crystallized temperature, the feeding device will activate so the continuous crystallization process can be repeated in a closed-loop.