Blending – CGB Gravimetric Blender

Introduction

Comet’s CGB series gravimetric blender provides even mixing, accurate weighing, and can precisely mix several types of material simultaneously. It can be installed on extrusion lines, injection molding machines, and blow molding machines. The machine is controlled by an advanced microprocessor with a digital display that is simple to calibrate. The self-compensation and calibration function ensures accurate material percentages.

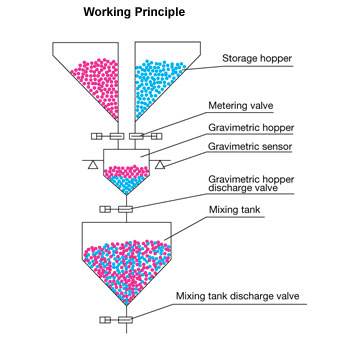

Load material hoppers with regrind, natural, color ,and additive, then set the recipe percentage for each material. Once the gravimetric blender is running, it will precisely weigh out each material according to the recipe.

Features

- Micro-scale metering accuracy of ± 0.1% when all material is blended using gravity.

- The auto calibration function performs every time material is weighed ensuring precise proportioning accuracy.

- The machine base features a magnet and manual side gate.

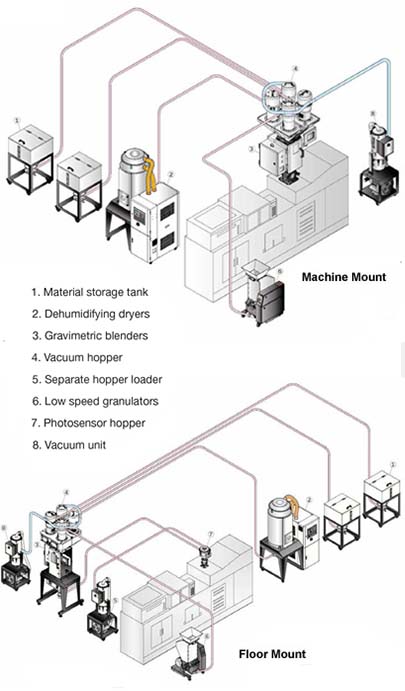

- Models CGB-600 and below are directly mounted on the machine.

- Models CGB-1200 and above are equipped with a floor stand, material storage tank, and pneumatic discharge valve.

- Easy to clean with accessible components and a large maintenance door.

- 100 recipes can be stored for future use.

- Audible and visual alarms with an alarm history screen.

- Ethernet communication function centrally monitors the operation when connected to a molding machine.

Options

- Low material level sensor for storage hopper provides advance warning for material shortage.

- Vacuum generator and central hopper receiver.

- Microscale pulse metering valve for CGB-40/200/600 to meter materials with proportions of 0.2% – 0.5%.

- Special material metering valve for metering sheets and irregular materials with diameters of .5 x .5 x .5 inches.

- Data collection function can read additive proportions, outputs, all kinds of materials’ total amounts and output rate of every lot of virgin or recycling material, color concentrate, and additives.

- Recycled material auto-compensation function.