CAC Compressed Air Chiller

Introduction

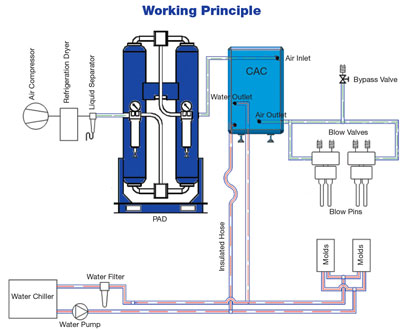

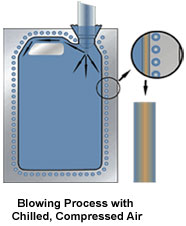

Comet’s CAC Compressed Air Chiller is an internal cooling system that distributes dry, chilled compressed air inside the product to accelerate heat removal from every surface. This process is guaranteed to reduce material stress and cooling time, as well as dramatically boost production by up to 50% (depending on the product).

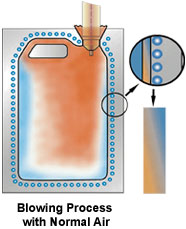

Cooling time is the longest part of the total blow molding process and is often extended to get the heat from the part all the way through the wall to the mold. During the mold cooling process, the internal surface of the part (hollow) remains at a much higher temperature than the external surface of the part. The difference between the external and internal surface temperatures in the mold causes material stress and poor product quality. But, extending the cooling time slows the production and shrinks the profit.

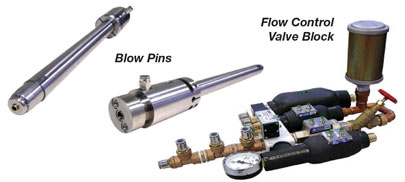

Blow pins are specially designed for individual products to guide the air to areas with thicker walls and areas that are not well cooled by the mold. Blow valves are designed to form the product with the highest air pressure available for the process, then drop the air pressure while chilled air is being exchanged inside the product.

Features

- Increased part quality because heat is removed from inside the molded product.

- Up to 50% production increase (depending on the product) and, in some cases, even higher.

- Suitable for virtually all blow molding machines.

- Five standard sizes available with a complete set of blow valves and individually designed blow pins.

- Microprocessor controller and graphic display for accurate control and data display.

- Easy integration into the production process with fully automatic operation.

- No maintenance required when good air and water quality (industry standard) is provided for the internal air cooling system.

- Low energy consumption and maintenance expenses.

- Quick return on investment.

- No CFC to harm the ozone layer of the earth’s atmosphere.

Specially designed blow pins guarantee optimal exchange of chilled air by guiding the air to areas with thicker walls and areas that are not well-cooled by the mold. Blow valves are designed to form the product with the highest air pressure available for the process, then drop the air pressure while chilled air is being exchanged inside the product.