SCM-E Econo Color Feeder

Introduction

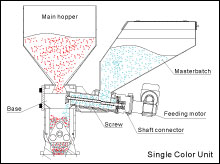

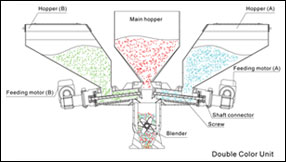

The SCM-E “Econo” series volumetric feeders come in six different models. All are screw metering units that accurately meter color concentrate, regrind, and additives directly to your molding machine or extruder feed throat. A gear motor with a gear ratio of 38:1 or 75:1 is coupled to a metering screw ranging from 12, 14 or 16mm diameter, providing ranges from 0.1~32kg/hr. Dual color feeders can be assembled from two single color units. Up to five components can be automatically mixed with four color feeders.

Features

- Chrome-plated metering screws for durability

- Easy to clean, disassemble and interchange

- Uses a carbon brush motor (carbon can be replaced)

- Three-tube hopper magnet at the base the single color feeder to absorb metal impurities preventing screw damage to the molding machine

- Dual color feeder comes with material hopper and a blender to evenly mix material (optional for single color feeder)

- External signals can be directly interfaced to the PLC controller. The current operation mode can then be recorded. Processing is unaffected by power failure so, when the power returns, operation continues where it left off.

- Rotating speed and plasticizing time are easy to adjust

- High and low starts can be selected for the injection molding machine connecting signal

- Fixed 60-second output testing

- Unit will stop and sound an alarm if it detects a motor fault

When the controller signals the dosing motor, operation starts. The dosing motor drives the metering screw. Color or additive in the hopper falls into the grooves of the rotating metering screw and is transported to the machine feed throat.

When the controller signals the dosing motors A & B, operation starts. The dosing motors drives the metering screw. Color or additive in hoppers A & B, fall into the grooves of the rotating metering screws and are transported to the machine feed throat.