CD-H Honeycomb Matrix Dehumidifying Dryer

Introduction

The CD-H series portable honeycomb matrix dryers offers the latest in matrix rotor drying technology and is used mainly to dry hygroscopic plastics. The largest unit can provide dry air

up to of 4,000 m3/hr.

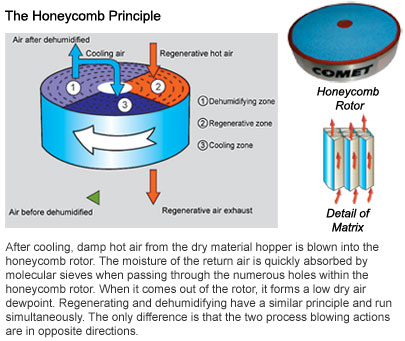

The honeycomb rotor provides superior strength, flow, and moisture transfer, and can attain energy savings of up to 35%. The rotor is made of a ceramic fiber/organic material and

sintered under high pressure, generating a bonded, open cell structure providing dewpoints lower than -40°F (-40°C).

This series of dryers are compact and offer easy access to all of its components. The heavy-duty powder coating, industrial-duty components and rugged design stands up to even the

harshest operating conditions.

Features

- Molecular sieve/silica gel and sintered honeycomb matrix rotor guarantees precise dehumidification.

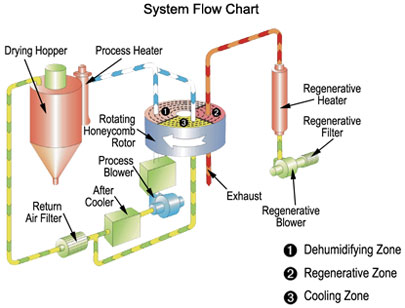

- Honeycomb rotor continually rotates through three separate air-flow loops to achieve dehumidification, regeneration, and cooling.

- Dewpoint monitor for accurate real-time measurement.

- Few moving parts and no valves ensure low maintenance.

- Twin cooling coils quickly and accurately cool down regenerative air and ensure a low return air temperature and dewpoint.

- The return air filter, mounted inside, prevents contamination to the honeycomb rotor.

- Non-proprietary PID microprocessor temperature control system with regenerative temperature settings, real time displays, and a 7-day timer.

- Achieves energy savings of up to 35%.

- Compact, portable design saves over 50% of floor space.

Options

- Portable dewpoint monitor is a convenient way to test dewpoint temperatures on different machines.

- Heat-resistant air pipe, cyclone dust separator and oil filter.

- Reach dewpoints of -58°F (-50°C).